Copyright Fullup SPRL — 2025

At Fullup, we have implemented different approaches depending on the type of client. These approaches differ in particular in the level of service that our client wants to have. Depending on the approach chosen, Fullup or the customer will choose the sensor to install (upstream or on site). Some examples are given below.

For a company wishing to offer telemetry solutions to its customers and then manage their supplies, we have implemented offers made up of IT services, support and installation tasks by certified technicians.

In order to meet the needs of our customers who wish to carry out all the installations themselves, we can provide formative documents and conduct demonstration sessions on request. So these companies can build up a stock of sensors and use our installation processes to carry out their projects with their technicians. We call this track "Install It Yourself".

For a private customer, wishing to install a sensor on their internet network, we have set up shop.fullup.be. 90% of our customers do not need an installer to configure their installation.

You have a doubt, we are here to help you!

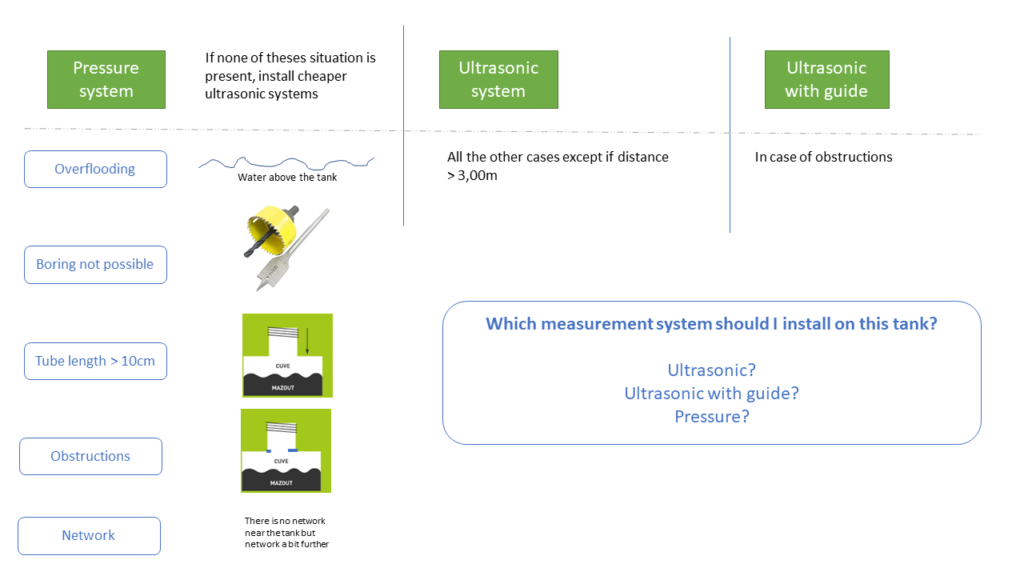

The choice of sensor is made in two stages: the choice of the measurement system, the choice of the communication system. In this article, we present in a simplified way on the basis of which elements the choice of measurement system is made. Here we present the elements on the basis of which an ultrasound vs pressure choice is made.

The first element on which the choice of sensor is based relates to the needs of the customer (in particular in terms of frequency of sending, price, type of liquid, ease of installation and precision).

Next come the constraints linked to the installation itself. In a non-exhaustive manner, the ultrasound sensors on battery being generally less expensive, they will be favored. 6 main elements can complicate the installation of this type of sensor:

QUESTIONS? We are here to help you ! support@fullup.be